Big Dimension: outer-diameter:ф80

Thin Wall: the thinnest wall thickness:0.5

Dimension tolerance: φ72.5(0/+0.019)

Roundness: 0.015(φ72.5)

Thin Wall: the thinnest wall thickness:0.5

Dimension tolerance: φ72.5(0/+0.019)

Roundness: 0.015(φ72.5)

Shine and Color:bright, semi-bright black, sand surface with white or black. Suitable material:5A05、6061、2A12 and so on.

Dimension control during oxidation: black oxidation directly add 3-6μm; black oxidation with extinction add 3-6μm; sand surface black oxidation ±10 μm; die-cast parts black oxidation add1-3μm;

Temperature without color different <200℃

Time with ultraviolet radiation tolerant:> 100H

Time for salt mist test :>200H

Big dimension: outer-diameter:ф70.5xф67.8

Thin wall ring type frame, less intensity.

Milling out circle and surface, easily lead to part deforming.

Anodizing and easily lead to part deforming

Dimension tolerance:0.019

Roundness: 0.019

Thin wall ring type frame, less intensity.

Milling out circle and surface, easily lead to part deforming.

Anodizing and easily lead to part deforming

Dimension tolerance:0.019

Roundness: 0.019

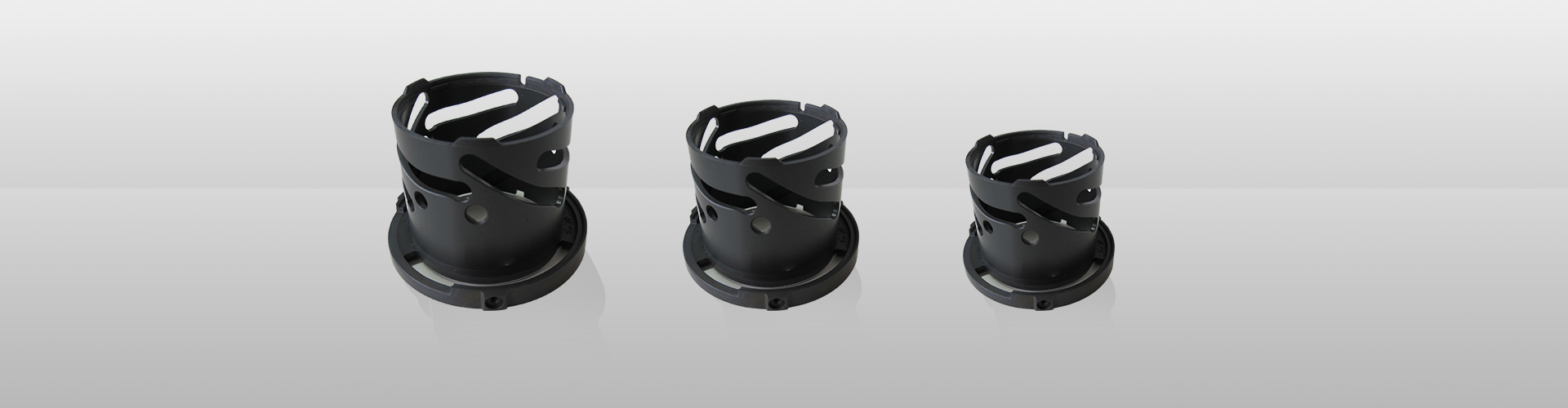

Material:Chinese A5056 pipe;

Structure:length 101,18 pieces of curves,Wall Thickness 2.3;the curve cam with the most curve grooves amount.

Curve Groove:width changing amount 0.01,curve groove same height 0.01,position deviation ±3′

Roughness Ra0.3,Roundness 0.01

Measuring:check the curve groove direct, groove position ±3′ is hard to measure

Structure:length 101,18 pieces of curves,Wall Thickness 2.3;the curve cam with the most curve grooves amount.

Curve Groove:width changing amount 0.01,curve groove same height 0.01,position deviation ±3′

Roughness Ra0.3,Roundness 0.01

Measuring:check the curve groove direct, groove position ±3′ is hard to measure